In the world of industrial materials, wax products are more than just finishing agents—they're vital to processes like molding, lubrication, sealing, and surface protection. But not all waxes are created equal. Choosing the right type of industrial wax can significantly impact the efficiency, performance, and durability of your products or processes.

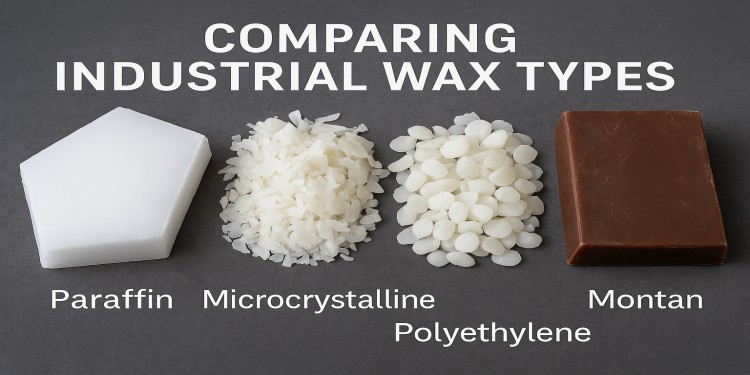

This article breaks down the most widely used types of industrial wax—Paraffin, Microcrystalline, Polyethylene, Montan, and Synthetic waxes—to help you make informed decisions for your business needs.

Overview:

Paraffin wax is a white or colorless soft solid derived from petroleum. It’s the most common and economical industrial wax.

Key Features:

Common Applications:

Pros: Affordable, easy to blend, readily available

Cons: Brittle at low temperatures, lower adhesion than other waxes

Overview:

Derived from the same petroleum base as paraffin but with a finer crystal structure, microcrystalline wax is more elastic and tacky.

Key Features:

Common Applications:

Pros: Excellent adhesion, flexible, heat-stable

Cons: Higher cost than paraffin wax

Overview:

A synthetic wax made from ethylene polymerization, often used to modify plastic properties or enhance coatings.

Key Features:

Common Applications:

Pros: Improves durability and finish, ideal for thermoplastics

Cons: Can be more expensive, limited biodegradability

Overview:

Extracted from lignite coal, Montan wax is a natural, hard wax used primarily in polishing and high-gloss applications.

Key Features:

Common Applications:

Pros: Superior gloss, tough and durable

Cons: Limited availability, higher price point

Overview:

Made through controlled chemical synthesis, synthetic waxes are tailored for high-performance needs where consistency and purity are critical.

Key Features:

Common Applications:

Pros: Precision performance, designed for niche applications

Cons: Higher cost, may require technical expertise to handle

| Wax Type | Melting Point | Key Strengths | Common Uses |

|---|---|---|---|

| Paraffin | 46–68°C | Low cost, water resistance | Packaging, candles, waterproofing |

| Microcrystalline | 63–93°C | Flexibility, adhesion | Cosmetics, rubber, insulation |

| Polyethylene | >100°C | Surface slip, durability | Plastics, inks, coatings |

| Montan | 75–90°C | Gloss, hardness | Polishes, leather, printing inks |

| Synthetic | Varies | High purity, custom use | Electronics, pharma, 3D printing |

The best wax depends on:

Recommendations:

At noor wax, we offer tailored industrial wax solutions backed by technical expertise. Whether you're casting metal parts, polishing leather, or improving packaging quality, we’re here to help you select the most effective wax for your operation.

Contact us now for product samples, technical data sheets, or a consultation with our wax specialists.

send comments